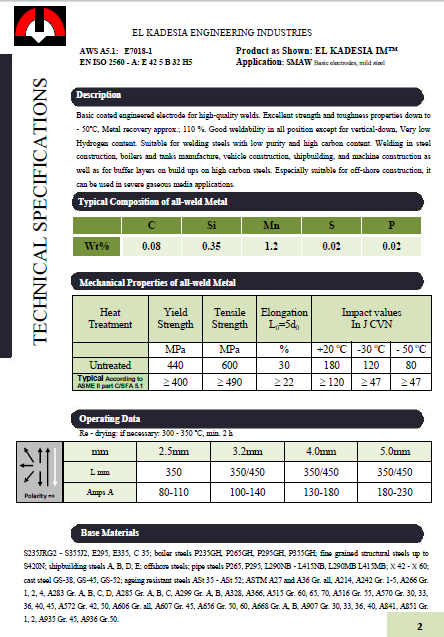

EL KADESIA IM E7018-1

| Description

Basic coated engineered electrode for high-quality welds. Excellent strength and toughness properties down to – 50ºC, Metal recovery approx.; 110 %. Good weldability in all position except for vertical-down, Very low Hydrogen content. Suitable for welding steels with low purity and high carbon content. Welding in steel construction, boilers and tanks manufacture, vehicle construction, shipbuilding, and machine construction as well as for buffer layers on build ups on high carbon steels. Especially suitable for off-shore construction, it can be used in severe gaseous media applications. |

Typical Composition of all-weld Metal

Mechanical Properties of all-weld Metal

Operating Data

Base Materials

S235JRG2 – S355J2, E295, E335, C 35; boiler steels P235GH, P265GH, P295GH, P355GH; fine grained structural steels up to S420N; shipbuilding steels A, B, D, E; offshore steels; pipe steels P265, P295, L290NB – L415NB, L290MB L415MB; X 42 – X 60; cast steel GS-38, GS-45, GS-52; ageing resistant steels ASt 35 – ASt 52; ASTM A27 and A36 Gr. all, A214, A242 Gr. 1-5, A266 Gr. 1, 2, 4, A283 Gr. A, B, C, D, A285 Gr. A, B, C, A299 Gr. A, B, A328, A366, A515 Gr. 60, 65, 70, A516 Gr. 55, A570 Gr. 30, 33, 36, 40, 45, A572 Gr. 42, 50, A606 Gr. all, A607 Gr. 45, A656 Gr. 50, 60, A668 Gr. A, B, A907 Gr. 30, 33, 36, 40, A841, A851 Gr. 1, 2, A935 Gr. 45, A936 Gr.50.

EL KADESIA E 7018-1H4

| Description

Basic coated engineered electrode for high-quality welds. Exceptional strength and toughness properties down to – 50 º C, Deposition efficiency about 110 %. Good welding in all position except for vertical-down, Very low Hydrogen content in the weld metal (under AWS container HD ≤ 4 ml/100g). The electrode is suitable for joint welding in steel, boiler, container, vehicle, ship and machine construction, and as well as a buffer layer for build-up welds with high-carbon steels. Suitable for welding steels of low purity and high carbon content. Particularly suitable for offshore constructions. CTOD-tested at -10 º C. |

Weld metal deposit analysis

Mechanical Properties of weld Metal

Operating Data

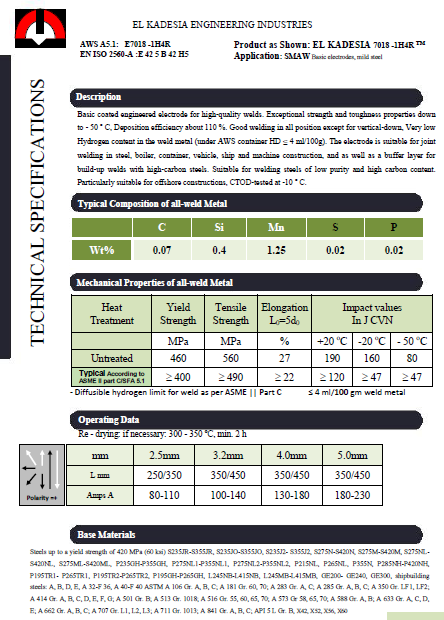

EL KADESIA E7018-1H4R

| Description

Basic coated engineered electrode for high-quality welds. Exceptional strength and toughness properties down to – 50 º C, Deposition efficiency about 110 %. Good welding in all position except for vertical-down, Very low Hydrogen content in the weld metal (under AWS container HD ≤ 4 ml/100g). The electrode is suitable for joint welding in steel, boiler, container, vehicle, ship and machine construction, and as well as a buffer layer for build-up welds with high-carbon steels. Suitable for welding steels of low purity and high carbon content. Particularly suitable for offshore constructions, CTOD-tested at -10 º C. |

Typical Composition of all-weld Metal

Mechanical Properties of all-weld Metal

Operating Data

Base Materials

Steels up to a yield strength of 420 MPa (60 ksi) S235JR-S355JR, S235JO-S355JO, S235J2- S355J2, S275N-S420N, S275M-S420M, S275NL-S420NL, S275ML-S420ML, P235GH-P355GH, P275NL1-P355NL1, P275NL2-P355NL2, P215NL, P265NL, P355N, P285NH-P420NH, P195TR1- P265TR1, P195TR2-P265TR2, P195GH-P265GH, L245NB-L415NB, L245MB-L415MB, GE200- GE240, GE300, shipbuilding steels: A, B, D, E, A 32-F 36, A 40-F 40 ASTM A 106 Gr. A, B, C; A 181 Gr. 60, 70; A 283 Gr. A, C; A 285 Gr. A, B, C; A 350 Gr. LF1, LF2; A 414 Gr. A, B, C, D, E, F, G; A 501 Gr. B; A 513 Gr. 1018; A 516 Gr. 55, 60, 65, 70; A 573 Gr 58, 65, 70; A 588 Gr. A, B; A 633 Gr. A, C, D, E; A 662 Gr. A, B, C; A 707 Gr. L1, L2, L3; A 711 Gr. 1013; A 841 Gr. A, B, C; API 5 L Gr. B, X42, X52, X56, X60

المراجعات

لا توجد مراجعات بعد.