|

THJ506Fe |

Iron powder type basic electrode

GB/T 5117 E5018 AWS E7018 ISO 2560-B-E4918 A

Applications:

It is suitable for the welding of carbon steel and low alloy steel structure, such as Q345, an so on.

Characteristics:

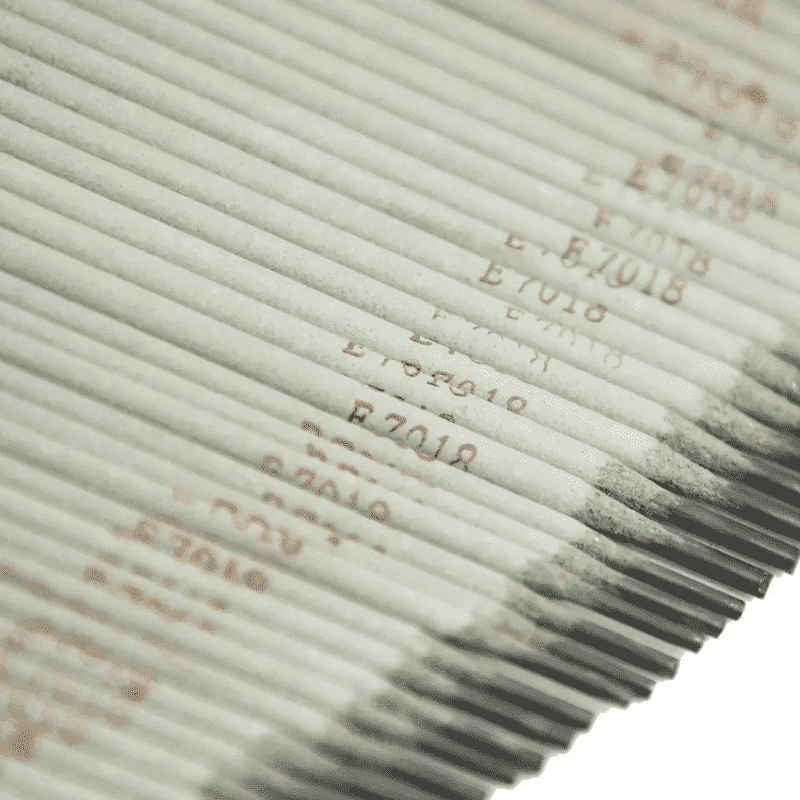

THJ506Fe is basic coated iron powder low potassium hydrogen type electrode. Both AC and DC can be used and can be all-position welding. It can reach excellent welding performance, good arc stiffness,little spatter, easy slag removal and good weld appearance,high deposition efficiency, and can reduce welding layers.

Welding Positions:PA,PB,PC,PD,PE,PF

Attention:

1.Electrode must be approved by 350-380℃ for 1 hour before welding, dry the electrode when use it.

2. The rust, oil, water and other impurities of the weld must be removed before welding.

3.You must use short arc welding,the swings should not be too large, narrow bead welding is appropriate.

4. To prevent producing arc porosity, arc plate should be adopted or use return method for arc welding.

DEPOSIT COMPOSITION(Quality Score): %

|

items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Requi-ements |

≤0.10 |

0.85- 1.40 |

≤0.65 |

≤0.030 |

≤0.035 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Typicl Resuls |

0.06 |

1.00 |

0.30 |

0.015 |

0.020 |

0.030 |

0.035 |

0.005 |

0.004 |

MECHANICAL PROPERTIES:

|

items |

Tensile Strength Rm/MPa |

Yield Strength Rel/Rp0.2 MPa |

Elongation A/% |

Charpy V-Notch KV2(J)-30℃ |

|

Requi-ements |

490-660 |

≥400 |

≥22 |

≥80 |

|

Typicl Resuls |

590 |

480 |

28 |

160 |

X-ray flaw detection: Ⅰ level

TYPICAL OPERATING PROCEDURES:(AC,DC+)

|

Diameter in(mm) |

2.5 |

3.2 |

4.0 |

5.0 |

|

Current in(A) |

60-100 |

100-150 |

170-210 |

210-250 |

Classification Society Certification:

|

Ship inspection agency |

ABS |

BV |

CCS |

DNV |

GL |

LR |

NK |

CWB |

|

Recognition level |

3YH10 |

3YHH |

3YH10 |

3YH10 |

3YH10 |

3YmH15 |

KMW53H10 |

E4918 |

المراجعات

لا توجد مراجعات بعد.