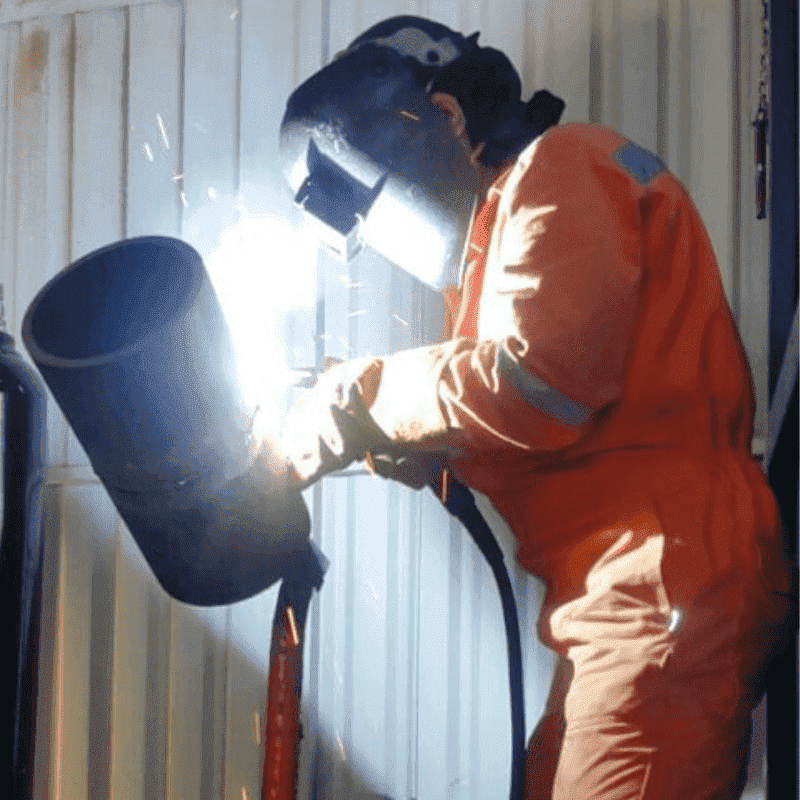

Welder Performance Qualification

Codes detail the requirements for performance qualifications of welders, welding operators and tack welders. Many codes do not demand that a Certified Welding Inspector (CWI) or a welding engineer conduct the necessary testing. Unless your customer specifically asks that a CWI or third-party do this, you can simply follow the code yourself to perform all testing. This, however, must be done by a competent professional that understands the code. We would highly encourage any fabricator to have a CWI on staff, or at the very least, have someone trained in visual inspection. Experience in the code being used would also be helpful.

Many customers call us to ask how they can get their welders qualified. It is important to first understand what qualification they need. Typically, this is their customer’s requirement and should be specific to the materials, processes and positions to be used in production. The actual evaluation of the tests specimens consists of just a few tests. These tests are:

- Visual Inspection (VT)

- Bend Test (face, root, side)

- Macroetch Test

- Fillet Weld Break Test

- Radiographic Test (RT) – can be done in lieu of bend tests

For the vast majority of cases you will only need to perform visual inspection and a fillet break test (for fillet welds) or bend tests (for groove welds). These tests and examinations are easily done and need not cost a lot of money. With a band saw, etchant solutions, a grinder and a bend test jig you will be able to perform 90% or more of the tests required to qualify your welders.

A very important aspect of qualification, whether it is for welding procedures or welders, is documentation. You must document everything. Although pictures are not required we recommend keeping pictures on file. With the ease of electronic filing this should be a no-brainer.

.

Watch a video now

المراجعات

لا توجد مراجعات بعد.