WHY DO YOU NEED A WELDING PROCEDURE SPECIFICATION?

Whether you have a small welding business or are a multinational manufacturing company, your ultimate goal should always be to create a high-quality product with a long lifespan.

No matter how experienced your welders are, to consistently provide welding quality of the highest standard you shouldn’t rely on them to simply guess the best way to accomplish a specific weld.

Instead, you should provide a list of directions and specifications to execute an excellent weld in any situation. To maintain consistently high standards you should implement a Welding Procedure Specification for every type of weld you action. At Technoweld, we provide quality welding inspection services and expert witness services to industries such as the Australian defence sector, to ensure world-class quality.

WHAT IS A WPS?

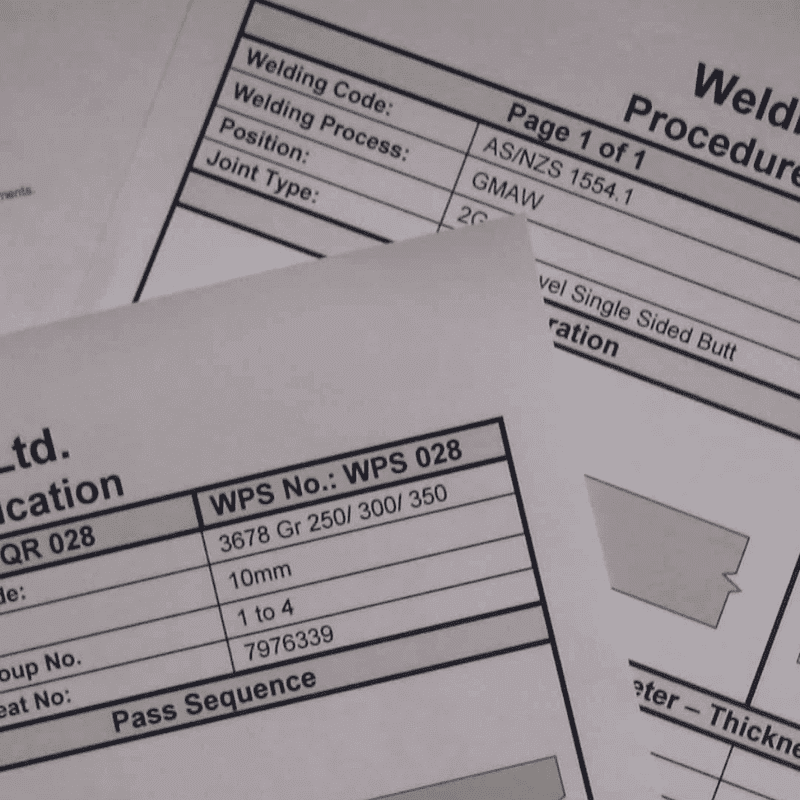

A Welding Procedure Specification, or WPS, is a formal written document describing standard welding procedures.

Like a recipe for welders, these procedures provide clear direction for your welders to make quality products that are up to code and industry standards. They will include any details and information that are required to make a desired weld.

These are proven and tested procedures that include but are not limited to, information such as the materials needed, the tools required, the processes to follow, the techniques to employ and finally confirmation of the desired outcome.

A WPS can go beyond just a great weld. Although a WPS will ensure the welded component meets design requirements, a WPS can also help you make hiring decisions.

You can employ welders and welding operators whose skills are in line with the WPS and a WPS can also help you complete a fast inspection with quick testing times. Since your employees will follow strict safety standards, you can also reduce the risk of company liability.

ADVANTAGE OF A WPS

A Welding Procedure Specification is essential for every welding company to have because it maintains quality standards across every weld. It isn’t just a nice guide to follow.

Under various Australian and international standards (eg.ISO 15612, ISO 15609), a WPS is required to ensure a stable weld.

Under the Work Health and Safety Act of 2011, business owners have an obligation and duty of care to construct and operate a safe plant. For compliance to the Act, welders need to ensure they are following correctly designed WPS.

In Australia, Standards Australia is thepeak non-governmental agency in charge of the approval of welding standards. Their 73 member group has created basic WPS for some of the most common welding types, including welding of carbon steels, stud welding, and welding stainless steels for structural purposes.

Because every company has different welds to complete, Standards Australia has not created WPS for every type of weld. If your company uses a weld that does not have a WPS, it is your obligation to create one.

المراجعات

لا توجد مراجعات بعد.